We leverage technology, maximize checklists and communicate thoroughly to deliver quality customer service, high participation in your food service program, and most importantly, joyful eaters!

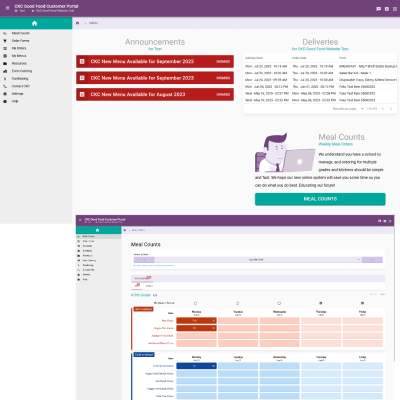

Intuitive Client Portal Makes Ordering Easy

Every CKC Good Food client has access to our custom-designed, easy-to-use client portal, which serves as the hub to your food service program's daily operations. Your Client Services Manager will walk you through the portal, explaining how to submit and change meal orders, download and print food production records, access helpful resources, and place orders for non-meal items like paper products.

Client Services Team Keeps Operations Flowing Smoothly

CKC Good Food believes the continuous support we provide to every client partner is as important as the quality meals we provide. Each client partner is paired with a Client Services Manager who visits your site/s regularly to observe your food service operations for service flow, adherence to proper procedures, and HACCP compliance; answer questions; address any challenges; and communicate any updates or procedural changes, whether a change required by the USDA or a company procedure. This hands-on, consistent support is key to your daily success and compliance with procedures and, if applicable, USDA guidelines.

Warehouse and Inventory Management Processes

Our Eagan facility, where we began operating in 2022, has a 30,000-square-foot commissary with a large warehouse complete with cold storage and seven dock doors. The expanded capacity and improved logistics have allowed us to elevate the quality, quantity and consistency of inventory on hand to serve a growing client base. Our inventory management processes have built-in redundancy to stay ahead of shortages and minimize substitutions in our menus.

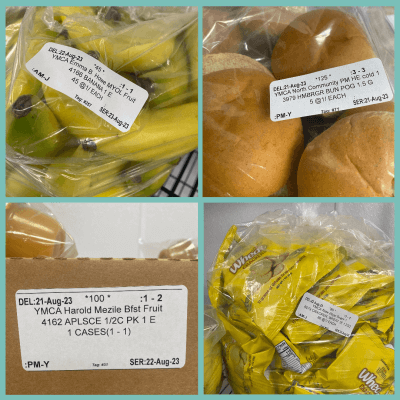

Tagger System Ensures Complete Meal Deliveries

CKC Good Food's central commissary produces more than 28,000 meals from multiple iterations of recipes in a typical day. Getting the right meals in proper quantities into the right vans to be delivered to the one right location is mind boggling.

Our proprietary tagger system accounts for every component of every meal, from inventory through delivery. A few days prior to a meal being served, tags are generated for each client site based on the day's menu and quantity needed. The day before service, the commissary's prep team readies the meals, placing a tag on each pan of hot food, bag of cold sides and box of bulk dry goods for every serving site. The next day, all the drivers go through their checklists for deliveries, counting each pan, bag and box to minimize chances of anything being left behind.